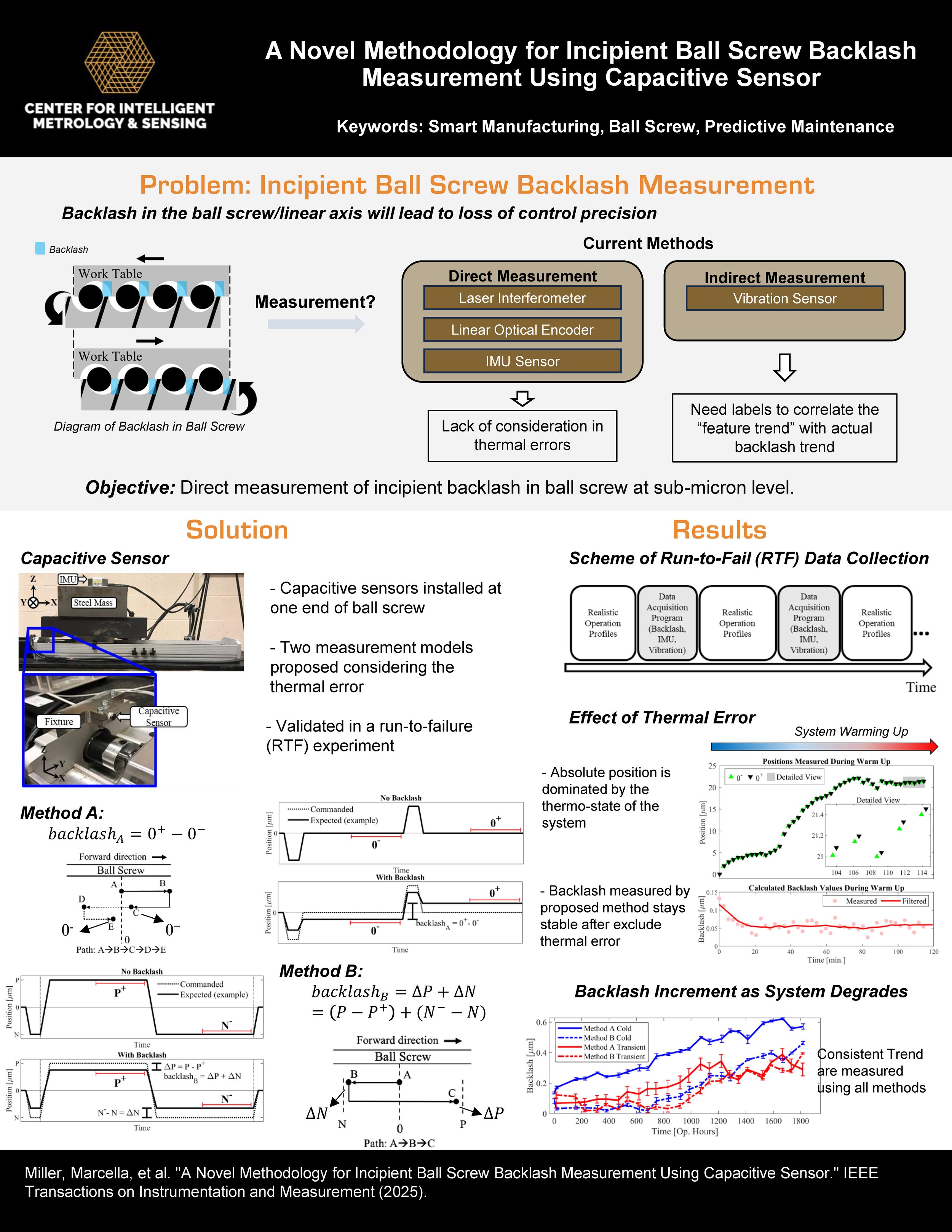

A Novel Methodology for Incipient Ball Screw Backlash Measurement Using Capacitive Sensor.

Creating a reliable indicator to describe the degradation of ball screws remains a challenging task. Current vibration-based prognostic methods are vulnerable to unknown noise or system disturbances. To address this challenge, our study offers a new method to monitor the developing trend of incipient backlash in a ball screw assembly using a capacitive sensor. The suggested method for measuring backlash is noncontact and in situ, providing direct evidence of ball screw degradation. Furthermore, a rigorous backlash measurement model, referred to as the path error model, is brought forward. This model serves as the foundation for a proposed procedure for backlash measurement. The method is validated in a run-to-failure (RTF) experiment, and the results indicate a promising upward trend in the backlash that agrees with the vibrational signatures.